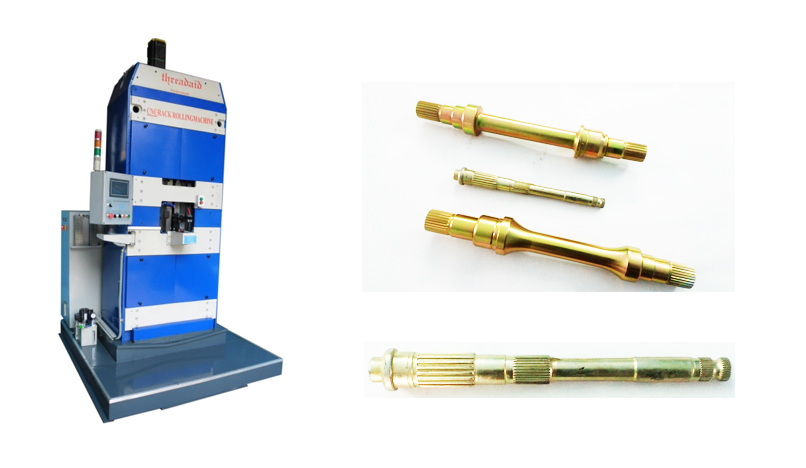

We are India's leading CNC Rack Rolling Machine manufacturers. This is a vertical rack rolling machine designed to produce Spline, Serrations, Oil grooves, Threads and special forms, using special racks as a tool for rolling most accurate splines and threads In a single cycle, we can roll, splines as well as threads simultaneously or two different splines one with helical and one with straight serrations. We can roll axle shafts for modern front wheel drive passenger cars having splines on both ends, in a single cycle.

One of our machines was tooled up to roll standard kick shaft of a popular motor bike having 1 module, (0.5) module and (0.43) module splines to roll all the three splines in a single cycle. For this set up threadaid was awarded “an innovative award” at Acme, Chennai in the year (2008) and we are the pioneers in this field. Now this tool layout is used by other manufacturers.

This machine also can be used for rolling CV Joints and various splines on the transmission shaft for modern automobile gear boxes. We can also roll skipped tooth simultaneously on both ends for orientation purpose.